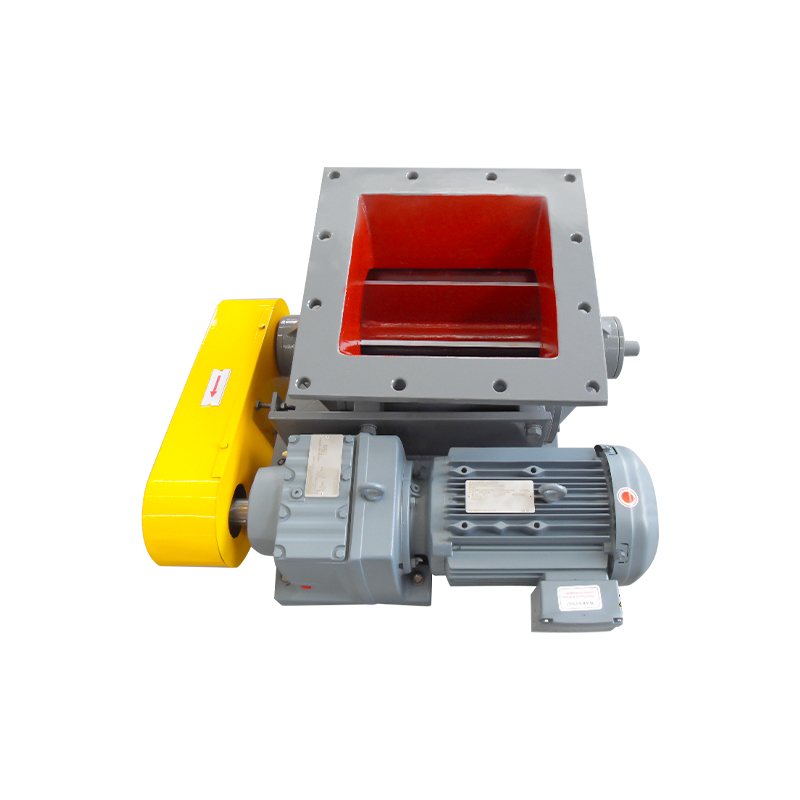

Carbon steel square port rotary discharge valves are essential components in bulk material handling systems. Their robust design allows them to efficiently control the flow of powders, granules, and other bulk solids from hoppers, silos, or feeders, making them critical for industrial processes that demand reliable and consistent material discharge.

Overview of Carbon Steel Square Port Rotary Discharge Valves

A carbon steel square port rotary discharge valve consists of a rotating rotor inside a square port housing. The rotor blades rotate to regulate material flow while maintaining a tight seal to prevent backflow or air leakage. The carbon steel construction provides durability and resistance to mechanical wear, allowing these valves to handle abrasive and heavy-duty materials efficiently.

Design Features and Advantages

Robust Construction

The use of carbon steel ensures strength, high wear resistance, and longevity, making the valve suitable for industrial environments where heavy or abrasive materials are processed. Its robust structure allows operation under high pressure and temperature conditions.

Square Port Design

The square port design provides consistent material feed, minimizing bridging and clogging issues. It ensures precise control over the discharge rate, which is critical in processes requiring accurate batching or dosing of bulk solids.

Sealing and Efficiency

Rotary valves are designed to maintain an airtight seal between the inlet and outlet, preventing material backflow and maintaining system pressure. This is especially important in pneumatic conveying systems, where maintaining airflow is crucial for efficient transport.

Key Industrial Applications

Food Processing Industry

In food processing, carbon steel rotary valves handle grains, flour, sugar, and other bulk powders. Their sanitary design and smooth operation reduce contamination risk, ensuring consistent flow for mixing, packaging, and dosing operations.

Chemical and Pharmaceutical Industry

These valves are widely used for transferring powders and granules in chemical and pharmaceutical production lines. The tight sealing and precise flow control prevent contamination, dust leakage, and material loss, maintaining quality and process efficiency.

Cement and Building Materials

Rotary discharge valves in cement and construction material plants control the flow of cement, sand, and aggregates from silos and hoppers. The wear-resistant carbon steel construction ensures long-lasting performance in abrasive material handling.

Agriculture and Feed Industry

In agriculture, these valves handle grains, seeds, and feed pellets. The square port ensures uniform feeding into conveyors or processing equipment, preventing blockages and supporting efficient plant operations.

Pneumatic Conveying Systems

Rotary discharge valves are essential for maintaining pressure differentials in pneumatic conveying systems. Their tight seal prevents air leaks, ensuring smooth and consistent transport of bulk materials through pipelines.

Advantages Across Applications

- Durable carbon steel construction resists wear and abrasion

- Square port design prevents clogging and ensures uniform discharge

- Maintains airtight seal to support pneumatic conveying

- Handles high-temperature and high-pressure conditions

- Reduces maintenance needs and extends service life

Comparison Table: Carbon Steel Rotary Valves vs Other Materials

| Feature | Carbon Steel | Stainless Steel | Aluminum |

| Durability | High | Very High | Moderate |

| Cost | Moderate | High | Low |

| Wear Resistance | High | High | Low |

| Maintenance | Low | Moderate | High |

Conclusion

Carbon steel square port rotary discharge valves are versatile components widely used across food processing, chemical production, cement plants, agriculture, and pneumatic conveying systems. Their robust construction, airtight sealing, and precise flow control make them indispensable for industries that require reliable, consistent, and efficient material handling.

English

English عربى

عربى