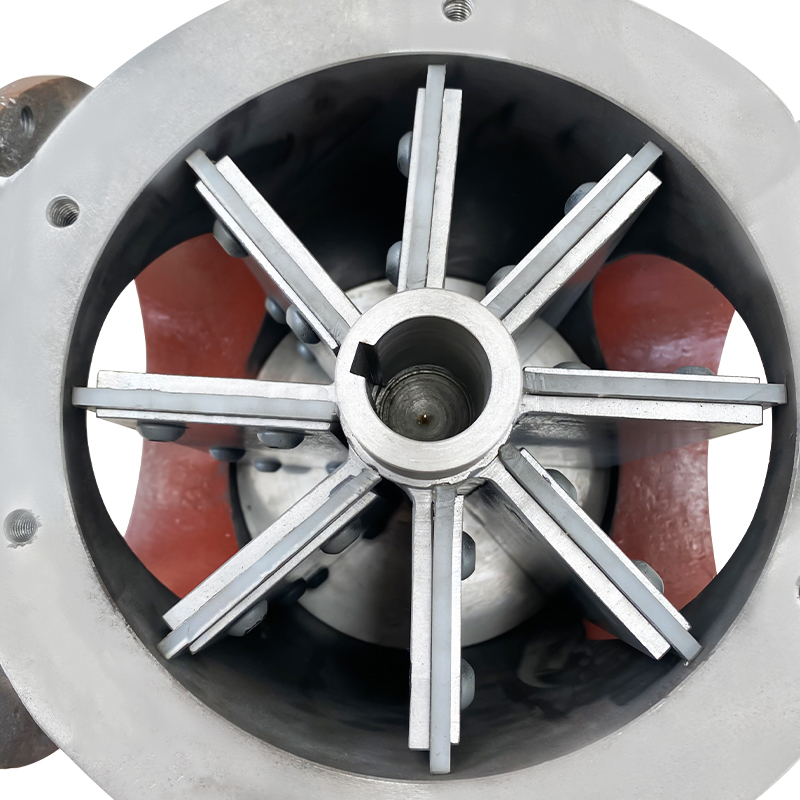

An anti-stuck rotary valve with bayonet type design is a specialized bulk material handling component used to regulate, discharge, and meter powders, granules, or pellets while preventing material build-up and blockage. In many industrial processes, conventional rotary valves struggle with sticky, cohesive, or fine materials that tend to adhere to internal surfaces. Over time, this adhesion leads to clogging, inconsistent flow, and unplanned downtime. Anti-stuck rotary valves are engineered specifically to address these challenges through structural, mechanical, and surface-level innovations.

Industries such as cement, chemical processing, food manufacturing, plastics, biomass, and pharmaceuticals rely heavily on rotary valves for continuous material transfer. When materials bridge or accumulate inside the valve chamber, efficiency drops sharply. The bayonet type anti-stuck rotary valve introduces an optimized internal geometry and quick-lock assembly concept that improves cleanability, reduces residue retention, and ensures stable operation even under demanding conditions.

What Makes an Anti-Stuck Rotary Valve Different from Standard Designs

A standard rotary valve typically consists of a housing, rotor, shaft, bearings, and seals. While this configuration works well for free-flowing materials, it often fails when handling moist, fibrous, electrostatically charged, or fine powders. Anti-stuck rotary valves incorporate additional design features that directly address the causes of sticking and material build-up.

The bayonet type structure allows for quick disassembly and reassembly without extensive tools, making internal inspection and cleaning faster. Internally, tighter rotor-to-housing clearances, self-cleaning rotor blades, and specialized surface treatments significantly reduce adhesion points. These enhancements ensure that materials do not linger inside the valve long enough to compact or cake.

Key Design Differences

- Bayonet locking mechanism for rapid access and maintenance

- Optimized rotor blade profile that minimizes dead zones

- Anti-adhesive coatings or polished internal surfaces

- Improved sealing systems to prevent fine material ingress

How the Bayonet Type Mechanism Enhances Anti-Stuck Performance

The bayonet type mechanism is a defining feature of this rotary valve design. Unlike traditional bolted housings, the bayonet system uses a twist-lock or quick-coupling method that secures the valve body and end covers firmly in place. This design reduces assembly gaps where material can accumulate and harden over time.

From an operational perspective, the bayonet mechanism allows maintenance personnel to open the valve quickly for cleaning or inspection. Frequent and easy access is critical in preventing long-term build-up, especially in processes involving hygroscopic or temperature-sensitive materials. By simplifying maintenance, the bayonet type design indirectly contributes to anti-sticking performance.

Internal Flow Dynamics and Self-Cleaning Action

Material build-up often occurs when flow velocity drops or when internal cavities allow particles to settle. Anti-stuck rotary valves are engineered with advanced internal flow dynamics that promote continuous movement of material. The rotor blades are shaped to create a sweeping action that dislodges particles before they can adhere to the housing.

In bayonet type anti-stuck rotary valves, the alignment between the rotor and housing is particularly precise. This precision reduces turbulence and stagnation points. As a result, materials pass through the valve chamber smoothly, maintaining consistent discharge rates and minimizing the risk of compaction.

Factors That Improve Flow Consistency

- Uniform rotor pocket volume for even material distribution

- Reduced internal ledges where powder can accumulate

- Continuous sweeping contact between rotor and housing

Material Build-Up Causes and How Anti-Stuck Valves Address Them

Material build-up is usually caused by moisture, oil content, static electricity, temperature variations, or particle shape. Sticky powders tend to cling to metal surfaces, while fine particles can lodge into micro-gaps. Anti-stuck rotary valves counter these issues through both mechanical design and material selection.

Surface treatments such as hard chrome plating, PTFE coatings, or electropolishing reduce surface energy, making it harder for materials to adhere. Combined with bayonet type precision assembly, these treatments create a low-friction environment that promotes clean discharge.

Comparison of Standard vs Anti-Stuck Bayonet Type Rotary Valves

| Feature | Standard Rotary Valve | Anti-Stuck Bayonet Type Valve |

| Maintenance Access | Time-consuming | Quick and tool-efficient |

| Build-Up Resistance | Limited | High |

| Operational Stability | Variable | Consistent |

Practical Applications Requiring Anti-Stuck Bayonet Type Valves

Anti-stuck rotary valves with bayonet type design are particularly valuable in applications where downtime is costly and material consistency is critical. Common applications include fly ash handling, starch and flour processing, chemical powders, pigments, carbon black, and recycled plastics.

In these environments, the ability to prevent build-up directly translates into improved throughput, reduced maintenance costs, and longer equipment life. The bayonet type valve design ensures that even frequent cleaning does not compromise alignment or sealing integrity.

Maintenance Advantages and Long-Term Operational Benefits

One of the most overlooked benefits of an anti-stuck rotary valve with bayonet type construction is its long-term maintenance efficiency. Faster access reduces labor hours, while reduced build-up minimizes wear on rotors and seals. Over time, this leads to lower total cost of ownership and more predictable production schedules.

By preventing material accumulation before it becomes problematic, these valves help maintain steady process conditions. This consistency is especially important in automated systems where fluctuations can affect downstream equipment performance and product quality.

Why Anti-Stuck Bayonet Type Rotary Valves Are a Smart Investment

Investing in an anti-stuck rotary valve with bayonet type design is not merely about solving a single operational issue. It represents a proactive approach to material handling efficiency. By combining smart mechanical design, easy maintenance access, and anti-adhesion features, these valves address the root causes of material build-up rather than just the symptoms.

For industries handling challenging bulk solids, this type of rotary valve offers a reliable, scalable, and cost-effective solution. Its ability to maintain clean internal conditions ensures stable operation, improved safety, and long-term productivity gains.

English

English عربى

عربى